Roller conveyors are some of the most common conveyor systems available

The manual or powered roller conveyors are some of the most commonly used for general warehouse and manufacturing because of their easy manual and powered options, allows different parts of the system to be powered in different ways. A great example of this is a manufacturing processes which require quality control or manual checking. The goods can be transported with a powered roller system through most areas and converted to a manual roller system allowing staff to manually check the items before returning them back to the powered system.

The manual or powered roller conveyors are some of the most commonly used for general warehouse and manufacturing because of their easy manual and powered options, allows different parts of the system to be powered in different ways. A great example of this is a manufacturing processes which require quality control or manual checking. The goods can be transported with a powered roller system through most areas and converted to a manual roller system allowing staff to manually check the items before returning them back to the powered system.

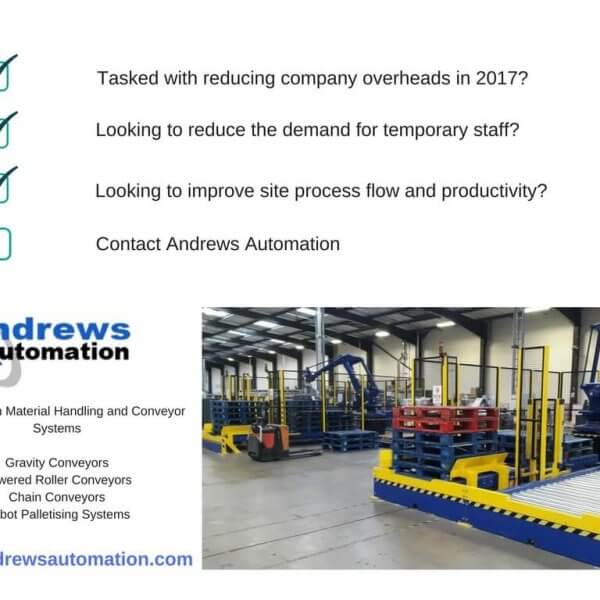

Andrews Automation recently designed and installed a ‘Turnkey’ solution of a manufacturer with a large warehouse. The system was powered by a range of Q89 rollers which was specifically designed and manufactured to handling palletise product up to 2000kgs. All Q89 equipment is easy to install and run, and offers excellent ROI. The manufacturer saw benefits including:

- Excellent ROI cost benefits

- Easy maintenance and servicing

- Modular design integration should it need to be extended in future

- High load capacity on normal and palletised products

- Longevity

Andrews Automation material handing systems for warehouses can be designed and tailor made to your exact specification. Andrews Automation have significant experience in all types of conveyor systems so are able to guide you in the right direction to get the best possible results for our automation solutions.