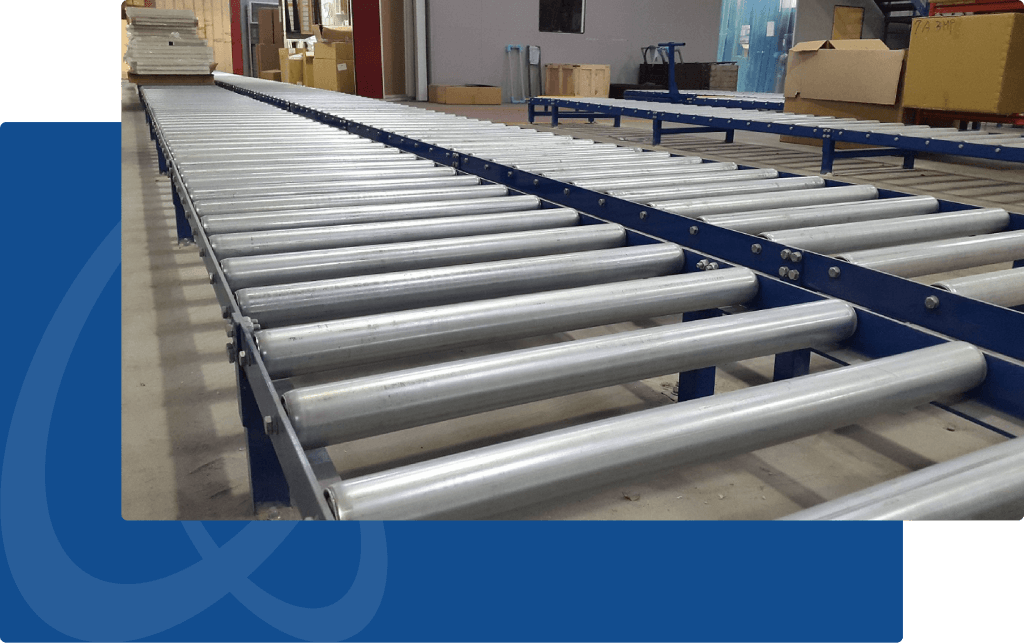

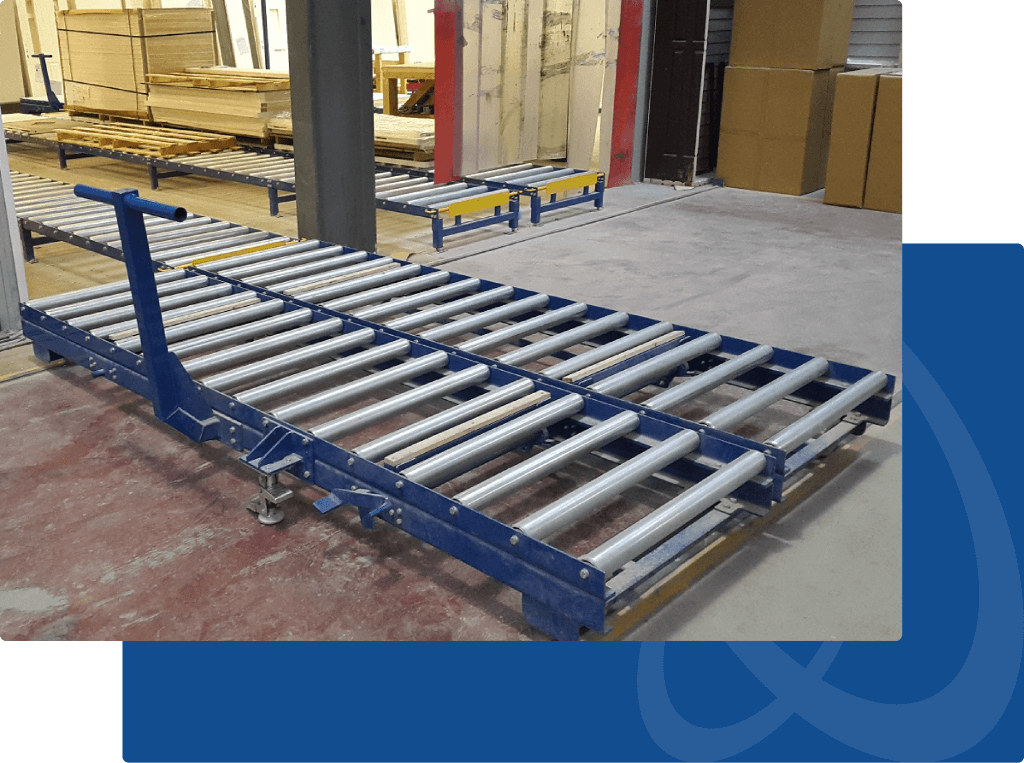

Gravity Roller Conveyor

Gravity roller conveyors, as the name suggests, simply uses gravity to transport products from point A to point B. Gravity conveyors are used in many industries as a cost effective solution to material handling requirements. Gravity roller conveyors require no power to operate, require very little maintenance, and they are easily repaired in the event of a breakdown.

Get a FREE Quote

Advantages Of Gravity Roller Conveyor

Andrews Automation Ltd are able to offer an in-house design service with the facility to design a roller conveyor to suit your needs

AAL are able to offer a reliable, long-term solution based on the client product to be transported, rather than making the client product fit a ‘standard range’ of roller conveyor. All roller conveyors are made to order in lengths and widths to suit customer needs, and are designed around client load requirements. AAL also incorporate specially designed end-stops and flip stops that allow for easy and safe handling of a multitude of loads.

Download Our Brochure

Download our brochure today to receive all the latest news, career opportunities, videos and much more…